Sedron® Technologies’ Janicki Omni Processor (J-OP) is a decentralized waste treatment system that kills pathogens while recovering valuable resources from fecal sludge, biosolids, and other waste streams. The J-OP aims to make responsible waste treatment economically attractive rather than a cost burden to society. It accomplishes this by using the waste stream to generate electricity, clean water, heat, and an ash product suitable for use as a soil amendment or construction material additive.

The J-OP is designed to be flexible, modular, and scalable to different markets and contexts. It can serve populations ranging from community-scale to city-scale in both developing and developed countries. With minor adjustments to the inputs, specific outputs can be optimized over others in response to market needs. For example, in locations where the value of electricity is high, the J-OP’s power production can be optimized. Conversely, in markets where clean water is especially valuable, the J-OP’s water production can be prioritized to increase the quantity of that output. This optimization can be done on the fly and does not require design or hardware changes on the J-OP itself.

THE PROCESS

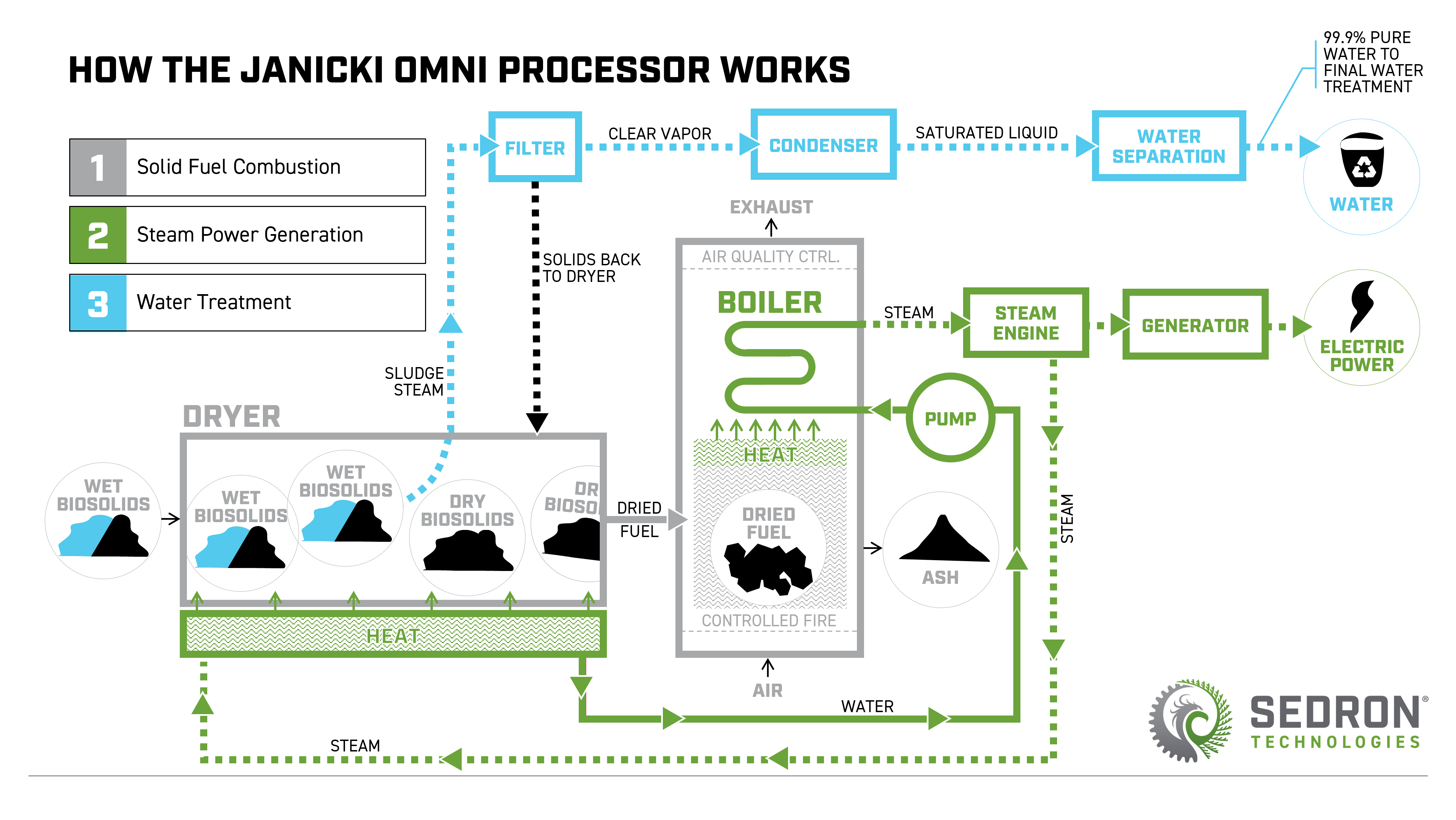

The Janicki Omni Processor (J-OP) is an innovative decentralized waste treatment plant that combines three well-proven, industry-standard processes into a single package:

SOLID FUEL COMBUSTION

It starts with solids fuel combustion. Fecal sludge, biosolids, or other wet waste streams enter a dryer where the moisture is evaporated. The dried, solid waste is now a fuel that is burned in a combustion chamber, reducing the solids to dry fly ash. The exhaust from the fire is conditioned and filtered to meet local, applicable regulations before it is released to the environment.

STEAM POWER GENERATION

The heat that is generated in the combustion chamber is used in a boiler to generate high-pressure, high-temperature steam. This steam is sent to a steam expander (e.g. steam engine or steam turbine), which turns a generator to produce electricity. This electricity is then used to power the whole J-OP AND there is often surplus electricity produced that can be sold back to the utility grid or used for other processes locally. The exhaust steam from the expander travels back to the heat exchanger surfaces of the dryer where it provides the energy required for drying the incoming wet waste. In transferring its heat back, the exhaust steam is condensed back to water and pumped back to the boiler, completing the Rankine cycle.

WATER TREATMENT

The water that is evaporated from the wet waste is captured. This vapor is filtered before being condensed back to water. If desired, this water can then be treated all the way to clean drinking water standards, or be used for other recycled or reuse water applications. Useful heat can also be captured from the condenser to be used for a variety of purposes.

How it Works

Want to know what makes our technology function? Have a minute? We’ll show you.